I recently uncovered a “transparency” page on Uncle Nearest’s website, but what I found only deepened my suspicions about their marketing practices. For a brand that touts honesty, their actions seem to tell a different story.

I have long felt Uncle Nearest has been deliberately vague about their product’s true nature. They oscillate between labeling themselves as “bourbon” or “Tennessee whiskey” for awards, yet their bottles consistently bear the generic “whiskey” designation (Class Type 140) – a catch-all for spirits that don’t fit established categories.

I toured their “distillery” last year further fueled my skepticism. While acknowledging the powerful historical narrative of Uncle Nearest, I found the operational aspects of the tour to be a facade. A pointed-out still was non-functional, and the barrel storage facility was largely populated by empty props. This suggests a deliberate effort to create an illusion of a fully operational, independent distillery.

The “transparency” page attempts to explain away the lack of a “Tennessee whiskey” label, offering a carefully constructed narrative that, upon closer inspection, appears to be a half-truth. I suspect the real reason lies in the restrictions imposed by their initial whiskey suppliers, a crucial detail seemingly omitted from their “transparent” explanation.

Uncle Nearest claims to have transitioned to distilling their own whiskey at DSP-TN-21144 in Columbia, TN, starting in 2021. However, looking into that DSP number reveals it shares an address with Tennessee Distilling Ltd. – a company whose primary business model is supplying bulk whiskey to other brands. While Uncle Nearest can technically claim to have their own DSP number, sharing an address with a known bulk supplier on a page dedicated to “transparency” strikes me as deliberately misleading. This isn’t transparency.

TRANSPARENCY – Uncle Nearest Premium Whiskey – 100 Proof from Tennessee Uncle Nearest Premium Whiskey – 100 Proof from Tennessee

Author: wadewood07

Tater Mentality on New Releases

Taters in the 1st market: The moment a product drops, they scramble to buy it and flip it on the secondary market, hoping to make a whopping $25 to $50 per bottle after shipping. Big dreams, right?

Taters in the 2nd market: They think they can pull off the same stunt, only to realize no one’s left to buy their precious bottles. But hey, they bought a case and actually like it, so it’s all good… or so they tell themselves.

Then it hits nationally, and taters swarm local retailers like it’s Black Friday. The phone calls are relentless: “Do you have it yet? I heard the early batches are better, so I need it NOW!”

Social media bourbon groups are flooded with posts of unopened bottles, each tater proudly showing off their “score.”

Every conversation between taters is a broken record: “Have you tried this yet?”

Fast forward three months, and those once-coveted bottles are gathering dust on the end caps of every major retailer. The hype is dead, and nobody cares anymore.

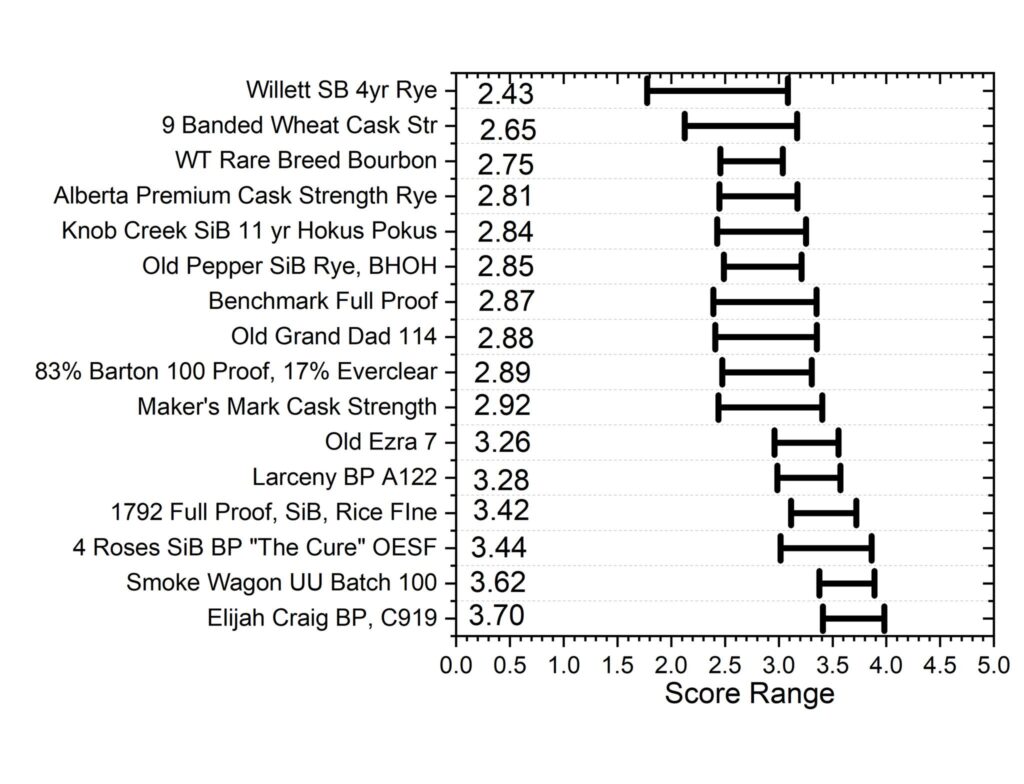

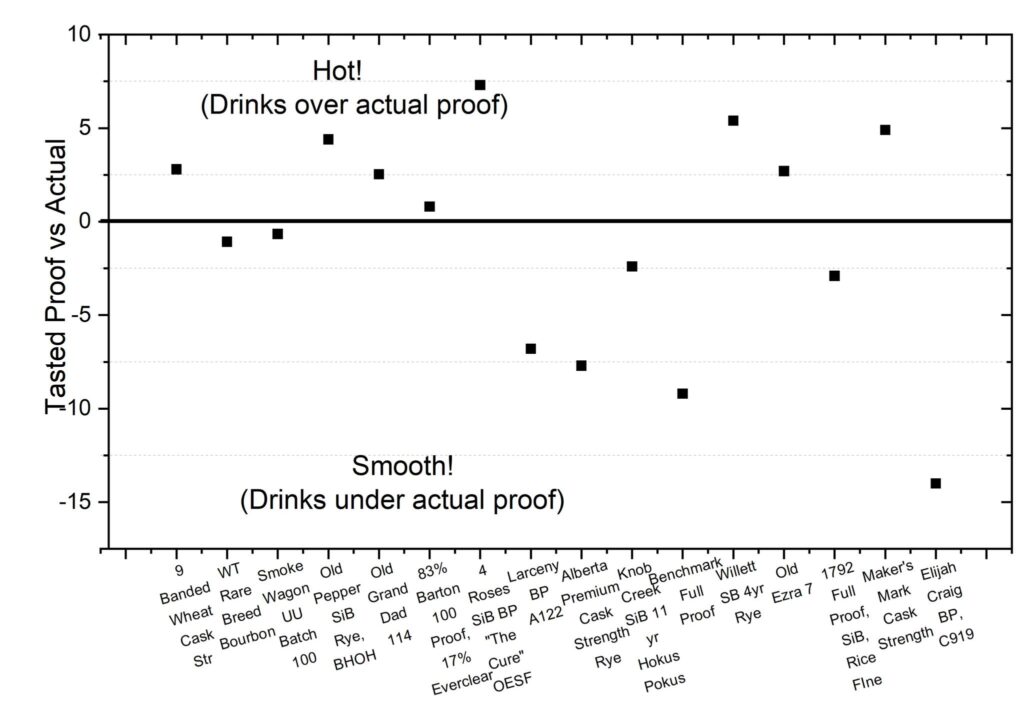

Some like it Hot, a HBS Elite tasting

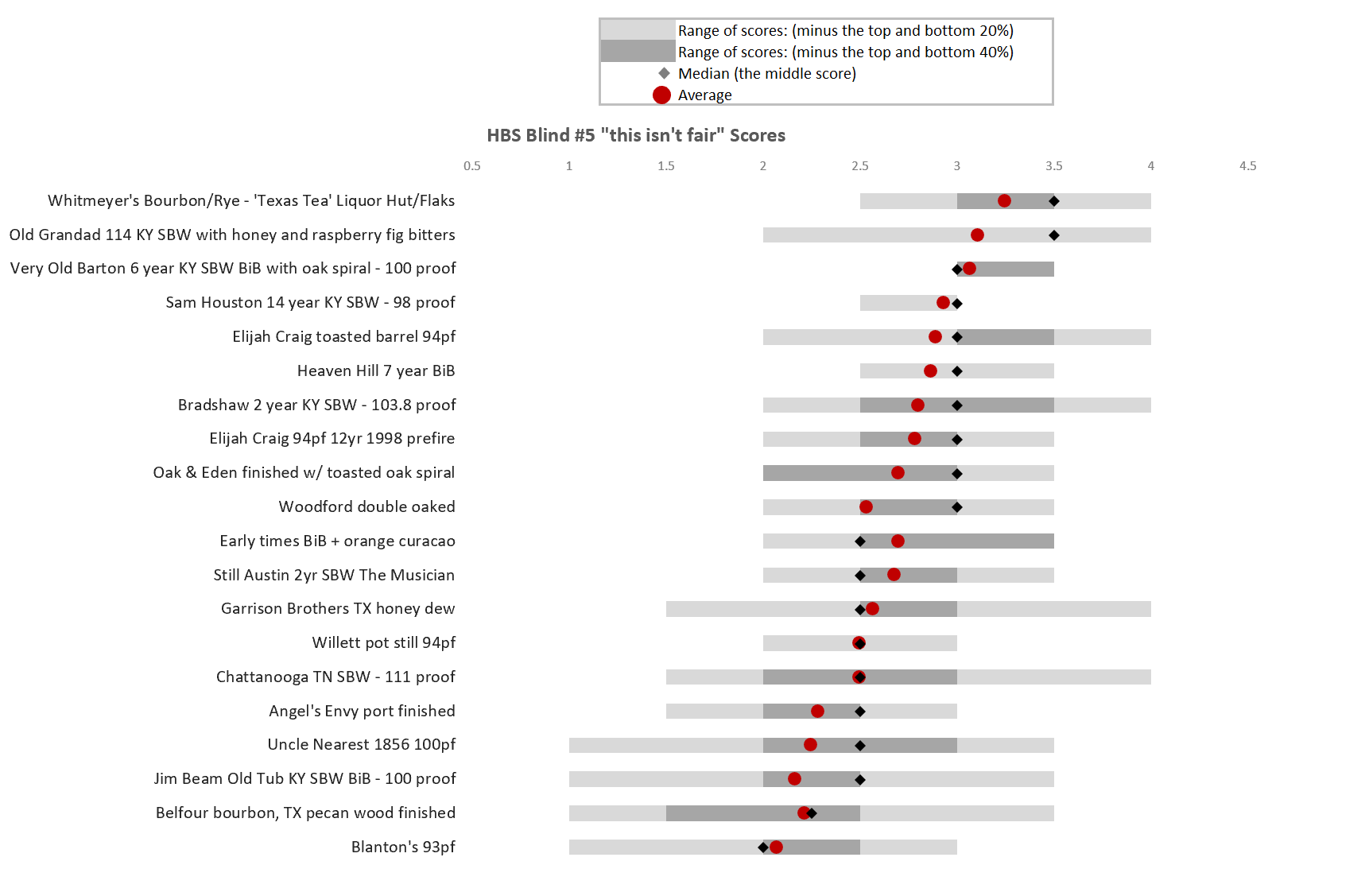

Time for another drinking for science post. This time it’s a blind tasting conducted with members in the Houston Bourbon Society, HBS, with 15 tasters of 16 high proof American whiskies. While I previously led 5 blind tastings in this group, this time I was a participant. Kevin Wyze organized this blind tasting and ran it well. It was a blast being a participant and sometimes very humbling when you see the reveals . Are these folks expert tasters? Well they do all have their HBS elite cards.

The scoring system was on a 0-5 scale, with 5 points being the best whiskey possible and 0 points being the worst. 2.5 points would be the middle of the road. Tasters turned in scores of 3 whiskies each week, so this tasting lasted 6 weeks. Tasters scored each whiskey on its own, preferably tasted on different nights.

The theme of this tasting was high proof American whiskies which ranged from 108.4 to 136.8 proof, with an average of 118.4 proof. Does proof cover up flaws in young whiskey? Which whiskey would blind tasters think tasted ‘hot’ or above their proof and which went down easy and tasted below their proof? Kevin did sneak in a poor man’s high proof whiskey concoction – 100 proof proof Very Old Barton which was kicked up with some Everclear to 115 proof.

The results:

On all my blind tastings, there were always a few surprises. Wild Turkey Rare Breed Bourbon scoring so low was shocking. The lowest score was Willett Rye, which was their own distilled rye, which did not surprise me. I scored it 0.5.

Lead in Dusty Decanters? A study.

This is a guest post written by a local bourbon enthusiast friend Kevin Wyss. It also draws on some earlier research done by Mike Jasinski.

(If you’re just here for the results and not a history and science lesson, scroll to the bottom)

The allure of “dusty” bourbon is seemingly universal in the current whiskey landscape, and while there’s no definition for what makes a true “dusty” bottle, many would argue that to qualify, the bottle must be at least 25 years old. Indeed this liquid from another century is held in such high regard that bottles which retailed for $10 in 1990 can now fetch well above $500 on the internet in backwater Facebook groups. Many purveyors of dusty bourbons argue that the flavors in these bottles simply cannot be matched by bourbon currently on the market, hence the hype and demand surrounding these bottles.

The history

In many cases, current production methods of bourbons have drastically changed in the new century. For example, a massive bourbon-fueled fire at the Heaven Hill distillery destroyed their entire production facility in 1996, sparking the transition to a more automated and modern distillation and barreling system. Now bottles of Pre-Fire Heaven Hill bourbon can fetch obscene amounts on the secondary black market. Whether this hype surrounding old Wild Turkey, Heaven Hill, Old Grand-Dad, Old Forester, Old Crow, Stitzel-Weller or Jim Beam dusties are worth the chase and cost is a discussion for a more experienced bourbon drinker, and not the topic of today’s article.

One of the cheapest and most common current forms of dusty bourbon is ceramic or porcelain decanters. These decanters were produced regularly starting sometime around the 70s, when the “bourbon glut” was just beginning. The “bourbon glut” resulted from a shift in Americans taste towards vodka, resulting in a drop in bourbon sales. Producers, which require 4-12 years to make their product, predicted that the drop in consumption would be temporary, and did not decrease production. Thus, a few years later, producers were sitting on thousands of gallons of well aged stock, with no demand for it. In a marketing ploy, many producers started releasing their bourbon not in standard glass bottles, but collectible and limited edition ceramic decanters. These decanters ranged from serious to downright goofy, taking the form of college mascots, animals, cars, guns, couch sized chess sets, spark plugs, wizards, clowns, states, and truly anything you can imagine. Importantly however, the bourbon inside these decanters were generally well aged stock, provided at rock bottom costs.

The science

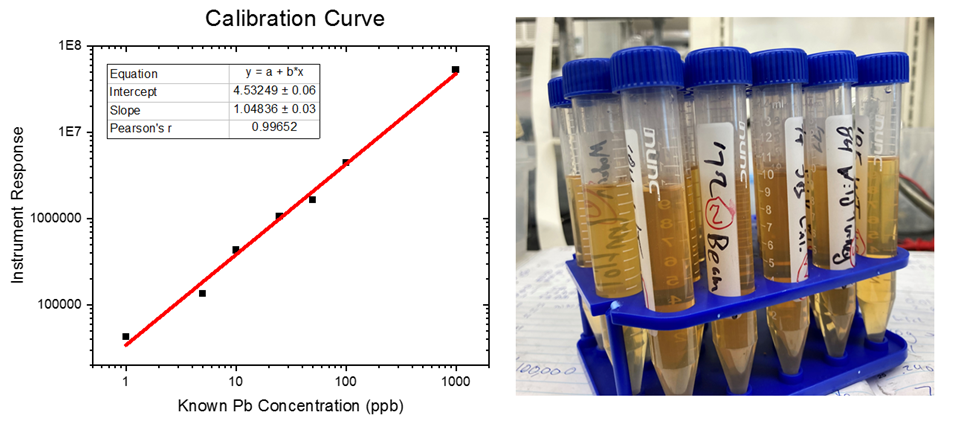

To circumvent these shortcomings, I decided it would be best to use a machine called an ICP-MS: an inductively coupled plasma mass spectrometer. These machines, used by the EPA and FDA to study the content of heavy metals in water, food, food containers, and soil, are incredibly sensitive – able to detect less than 1 ppb of lead (or 0.0000001%) in water. Basically an ICP-MS works by injecting the liquid sample into a super-hot flame (17,500 °F). This basically strips everything down the bare atoms (ions) present in the sample. The different atoms (ions) such as lead, are then sorted by weight and measured with very high precision. One slight complication here is that the tannins, ethanol, and other organic compounds which make bourbon taste so good, will make soot upon injection, which can complicate the readings. So, to overcome this, I added an acid and peroxide digestion to break those compounds down. Then, I could centrifuge the samples to remove the tannins and flavor molecules that had settled out after digestion – with all the lead remaining in the solution. I then removed the ethanol using rotary evaporation, so all I was left with is a solution of acid and water, with all the lead still dissolved in the samples. I used an internal standard during the test to make sure that the testing of the samples was consistent and reproducible. To figure out the unknown concentration of lead in the samples, it was compared to a calibration curve – where you make solutions of a known lead concentration and extrapolate those results to the bourbon samples. The results of the bourbon samples will only be as accurate as the calibration curve is – the calibration curve I made had an accuracy of 0.996, so I stand by the results.

The results

So, using the ICP-MS I have access to, I ran some samples of dusty decanter bourbon to screen for lead content. Many, many thanks my fellow bourbon friends for providing the dusty samples – I know how valuable and sentimental they are to be simply given away for free.

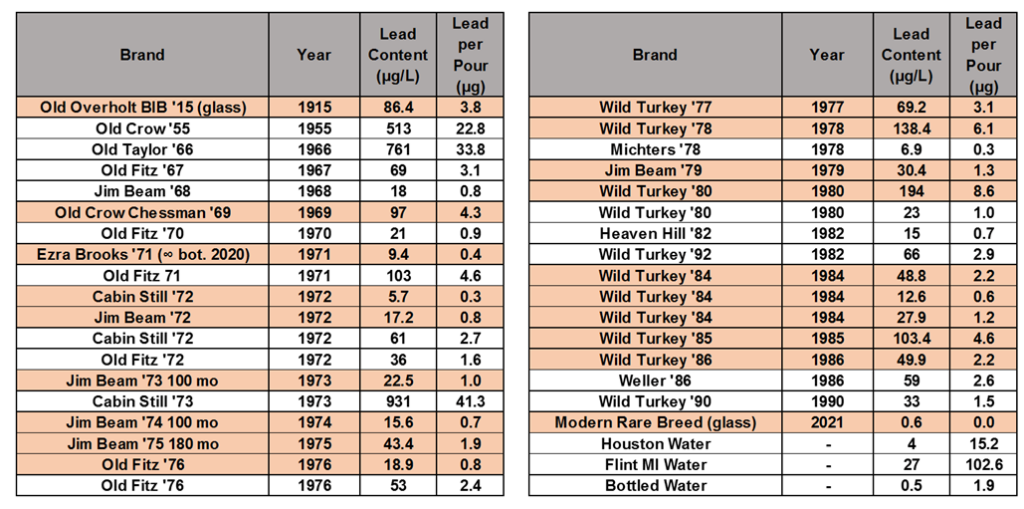

I also found one other bourbon-loving chemist that had done a very similar study in 2013 – Mike Jasinski who under user name michaelturtle1 had posted data on the straightbourbon.com message boards. So, here is the data table combining all of the samples we tested, with the samples I tested highlighted. These show the amount of lead in one 50 mL pour. The amount of lead in one pour of bourbon is compared to the amount of lead in 1 gallon of bottled water, Houston tap water, and tap water from Flint, MI during the ongoing lead pipe crisis in the bottom of the right table.

The average pour of the 33 dusty decanters tested contains 4.9 μg of lead. However, the deviation from decanter to decanter is huge – ranging from 41.3 μg/pour to 0.3 μg/pour.

Modern Wild Turkey Rare Breed from a glass bottle was used as a control – showing a lead content of 0.03 μg/pour. Some notes on two of the samples: the Old Overholt 1915 was a glass bottle, not a decanter. This was included to see if significant amounts of lead were in distillers pipes, solder, stills, or tanks, which might carry over to the final product. The Ezra Brooks 1971 sample is not the original juice: I got that decanter as a gift, empty and have turned it in to an infinity bottle. I’m not sure how fast the leaching of lead happens, or how much lead was in the original bourbon, but from a sample size of 1, it seems like using old ceramic decanters as an infinity bottle may be a safe practice.

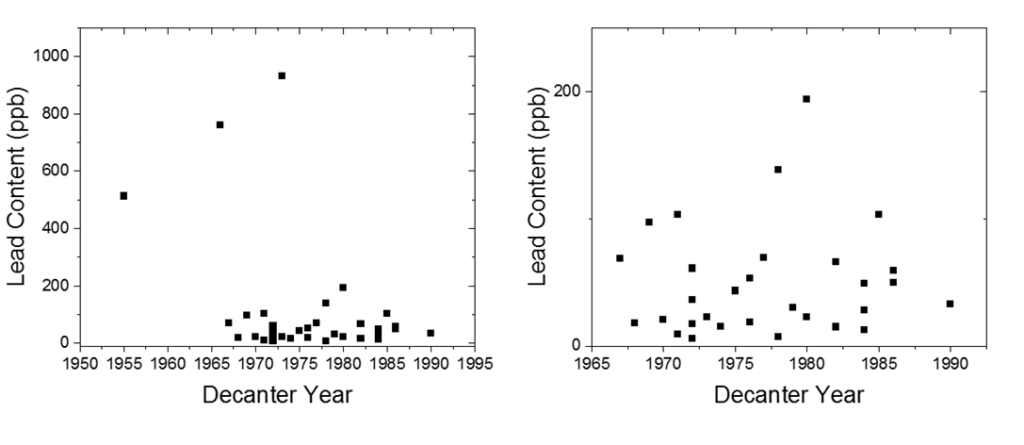

Here is a plot showing the lead content versus the year of the sample. Keep in mind that US lead laws changed a lot in the 20th century – lead solder for pipes was used well into the 1970’s, lead paint was outlawed in 1978. Lead in cookware and ceramics was a problem well into the 1980’s.

The biggest outliers with the most lead, all came before 1974, but besides that I was really surprised to see that there wasn’t a strong correlation between the year the decanter was produced with lead content. Large differences between decanters produced in the same year and by the same company was also interesting to me, but may result from storage conditions or differences in the decanter production process. I was intrigued to see the massive difference in lead content between a glass bottle of modern bourbon (containing barely more lead than bottled water) and the 1915 glass bottle of Old Overholt BIB. Despite the bottled-in-bond distinction and lauded history of the distillery, significant amounts of lead were present in the whiskey. This speaks to the lack of laws and checks in place in the early 20th century regarding lead, which I find interesting historically.

The takeaway

My main take home message here is that if consumed in small amounts, all decanters I tested are safe. Drinking 1 gallon of Houston tap water, you ingest ~15 μg of lead. A 50 mL pour from a decanter I tested will give you 0.3-41.3 μg of lead, at an average of 4.9 μg of lead. The CDC says to safely stay below 250 μg of lead ingested per day. Typical developed countries usually ingest less than 50 μg/day. So even drinking a pour of the highest lead containing decanters isn’t going to get you close to CDC daily limits, assuming you have a normal diet and life. Lead is purged from the body with a half-life of about 3 weeks. So, if someone did multiple decanter pours per day, every day for two weeks, you might encounter some issues. But even that I’d say is unlikely – so hunt on and enjoy those dusty decanters.

Drinking for Science Twofer

Today’s post is a drinking for science twofer. First, I’ve added to my testing projects on “Do spirits change in the bottle once opened?”, but this time with rum. Second, is a blind tasting of modern era Wild Turkey with bottles from 2010, 2015 and 2020.

I’ve tackled the question of “Does bourbon change once the bottle is opened?” 3 different times. My conclusions are that it does not change enough to be perceivable when stored up to 1 year with a good seal, out of bright light, normal room temp, and a fill level at around 50%. You can read about this info here – https://tater-talk.com/2018/08/30/did-my-bourbon-change-in-the-bottle-1-year-test/

Given my past conclusions, I have wondered if heavily peated scotch or higher ester rums would result the same. Are these esters more volatile? One way to find out is to test it. I purchased 3 bottles of Stolen Overproof Rum 375ml from the same store on the same day. On Jan 1, 2021, I poured one of these into a 750 ml bottle. Over the next 12 months, I opened that bottle 28 times and swirled it around exposing it to fresh air. The bottle was well sealed each time and stored in a dark cabinet at normal room temperature. On Jan 20, 2022, I had 11 tasters over for a triangle blind tasting. The other 2 bottles of Stolen were opened right prior to the test. Each taster had 3 Glencairn glasses without knowing which glass had which sample. The objective was to see if they could identify the odd sample. I also gave them a choice of saying no difference, though none elected that option.

If the testers randomly guessed 33.3% would luckily identify the odd sample. In my test 6 of the 11, 54.5%, were able to correctly identify the odd sample which is roughly 1.6 times the random guess odds. My group of tasters are all folks who routinely drink spirits neat and would be considered above the average consumer in a test like this. Still, 45.5% were not able to identify the odd sample. Of the 6 that identified the odd sample, most thought it was the worst of the three, but all commented the differences were subtle. Unlike my bourbon tests, I think the results here indicate that some type of small changes likely occurred. I think storing the bottle half full and opening it a total of 28 times is well above normal and makes for a good test. I still think spirits are remarkably stable once opened if you follow best practices of storing bottles upright, tightly sealed, out of any bright lights, and in normal room temps. If you get down to the last few pours in a bottle, either finish it off or, if you want to hold on to some, transfer to a 50ml glass sample bottle and properly label it.

For you stat nerds and other trolls, I’m well aware I didn’t have a N number of 15. Take what you want from the data given, but no need to give your opinion until you have ran similar tests, which are easy enough to do, and published it.

For my fellow Wild Turkey 101 fans, I put together a blind tasting of modern era WT 101 with bottles from 2010, 2015 and 2020. This was the same group of 11 tasters. I provided a score sheet and asked the tasters to rank in their order of 1st, 2nd and 3rd place. I will say I learned my lesson and never again will I attempt a twofer test in one night, some of my tasters left indecipherable markings instead. Perhaps vanity was the cause, as maybe they did not want to be perceived as having scored this wrong? The scores of the 8 tasters that correctly followed instructions are as follows:

| WT 101 | 2010 | 2015 | 2020 |

| 1st place | 5 | 2 | 1 |

| 2nd | 2 | 5 | 1 |

| 3rd | 1 | 1 | 6 |

I’ve since had a chance to sit down with these 3 multiple times, although not blind. Honestly, I go back and forth between favoring 2010 and 2015. Both are better to me than the 2020. This is not knocking current WT 101 as I still think it’s one of the best values currently in bourbon.

How to stop FOMO and enjoy bourbon again

During this ongoing bourbon boom, somehow retail prices of $80 to $200 per bottle of bourbon became normalized. The masses that jumped into Bourbon over the past 3 to 4 years have bought into the fallacy that price equates to quality or rarity. This is a result of masterful manipulation by spirits companies. The chairman of Diageo, Javier Ferrán, said it best, “A key driver of perception of quality is price”.

One factor driving this is the influence from online whiskey reviews via bloggers, youtubers, tik tok, instagrammers, etc. Those new to the game errantly give these folks credibility. Their motivation to review these overpriced whiskeys is largely that they are given free media kits and want to continue to receive free whiskey samples from them. It wouldn’t matter if they bought these bottles from a retailer as there is only one opinion in the world that is important, you and your palate! Seriously, go right now and unsubscribe from any site/person that reviews whiskey online, and indefinitely delete your patreon account. Once that is done, come back to continue reading.

Here’s the deal. Most of those $80-$200 bottles are put out by NDPs, non distilling producers, who sourced overpriced whiskey through a broker. 99% of the time this whiskey is distilled by one of the major US whiskey distilleries. So, until you know the profile of what the major distillers put out and which bourbons align with your palate, you are chasing waterfalls. Just stop! The great news is that these major producers put out plenty of bourbon that is affordable and widely available for the most part. Below is a list from the majors to buy next if you haven’t tried them.

Some of the majors have multiple mashbills so some of them have 2 suggestions. With a few possible exceptions, these should be easy to find at any decent liquor store in the US and for under $30 a bottle.

-Barton – Very Old Barton 100 proof

-Buffalo Trace – Buffalo Trace. Wheated mashbill – Weller Special Reserve

-Four Roses – Four Roses yellow label (now a tan label)

-George Dickel – Dickel 12

-Heaven Hill – Evan Williams or Elijah Craig. Wheated mashbill – Larceny

-Jack Daniels – Jack Daniels black label

-Jim Beam – Beam Black or Knob Creek. High rye mashbill – Old Grand Dad 100 proof

-Maker’s Mark – Maker’s Mark

-MGPi – they have just started selling their own brands in certain states so if it’s available in your area then look for George Remus Bourbon; this will be the exception on price and more like $38. If George Remus is not available, then look for any Straight Bourbon which the back label states “Distilled in IN”.

-Old Forester – Old Forester Signature 100 proof

-Wild Turkey – Wild Turkey 101

-Willett – Old Bardstown 90 proof square bottle – The square bottle is their own distillate

-Woodford Reserve – Woodford Reserve

These are all the real deal Straight Bourbon Whiskey with no flavoring or extra barrel finishing/staves added. They are all aged at least 4 years. Try all these either by buying a bottle or by buying a pour at your local watering hole. Narrow down your preferences to figure out your favorite. I could tell you my favorite, but this ain’t a whiskey review site. Once you have a favorite, explore other options from the same distillery. The next time you buy a more expensive hyped up bottle, because I know you taters still will, compare them to each other. If your favorite from the list costs $25 and the new hyped bottle was 4 times the cost, ask yourself if the new one is 4 times as good. Is it even better?

I know if you truly take this approach, you will splurge way less often on these hyped bottles and you will begin to enjoy bourbon again.

George Dickel is Bourbon

George Dickel, which is owned by Diageo, recently cleared a new label for George Dickel and for the first time called the product Bourbon instead of TN Whisky. Both Jack Daniels and George Dickel have always met the legal requirements to be called Bourbon although they elected to designate themselves as TN Whisk(e)y. Nothing about the Lincoln County Process prevents a whiskey from being bourbon.

Now what surprised me was that George Dickel used a Diageo address in New York in the Produced By statement on the back label.

But since this was now labeled as Bourbon and not TN Whiskey, this label failed to meet 27 CFR 5.36 (d). My readers likely know this code requires the actual state of distillation to be on the label on certain types of American whiskey if the Produced by or Bottled by statement is different than the actual state of distillation.

I contacted Diageo and the TTB about this clear label code violation. The TTB gave me their typical line; we will investigate it and take action as appropriate. Diageo did get back to me and after a week later they responded back that a new COLA label submission had been filed which now says distilled and produced at Cascade Hollow in Tennessee. I also checked on the old label with New York and it has now been surrendered.

The new label:

I would hope this puts an end to the false argument that Jack and George aren’t bourbons. But since many uneducated fools still think Bourbon can only be made in KY, I doubt it does. In the meantime, I’m looking forward to this release of 8-year Dickel Bourbon.

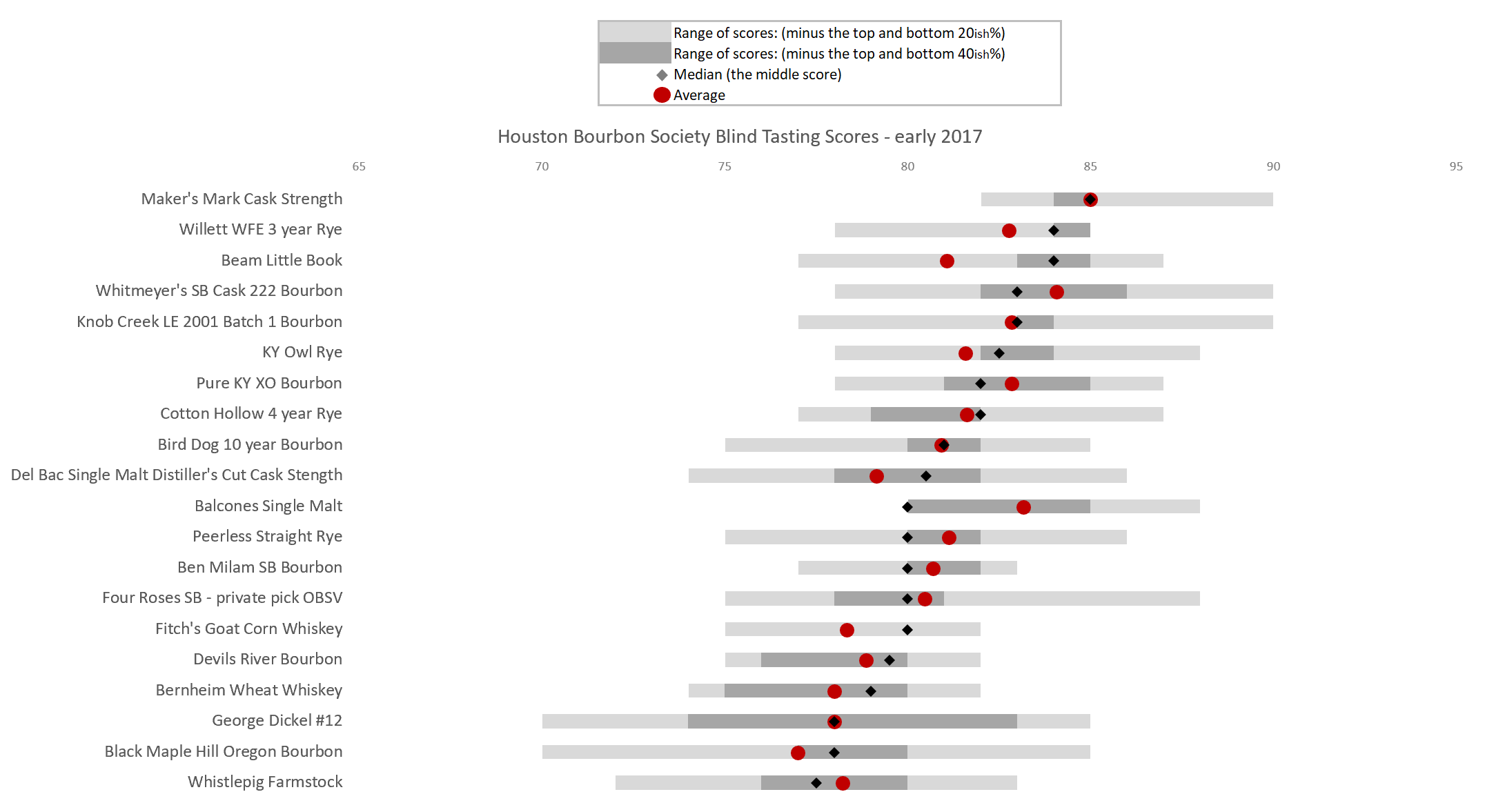

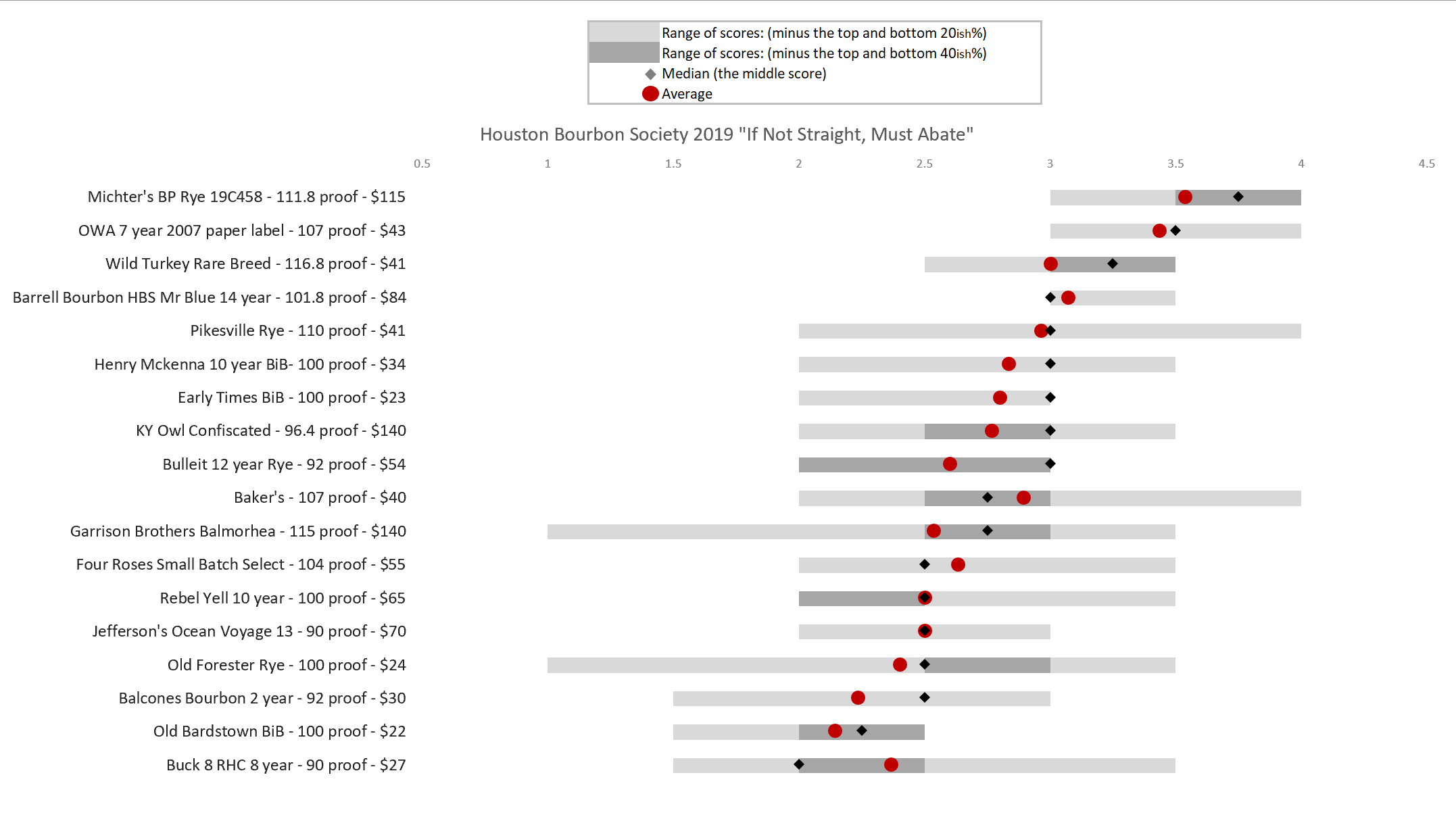

5 Blind Whiskey Tastings Results

In my local bourbon group, Houston Bourbon Society, I have run 5 group blind tastings. Each time it has included between 18 to 21 whiskies with 15 tasters. Why 15? Because a 750ml bottle breaks down neatly into 15 samples of 50ml each. Each taster paid the actual cost for the samples. Most of the bottles were obtained at a store for normal SRP. I sometimes included a dusty bottle from my bunker. Each tasting had a loose theme as described below. Beyond the theme, the tastings were completely blind, meaning the tasters had no clue which bottles were included the lot. The tasters picked up the samples and turned in notes on a few each week until it was completed.

The graphs below show the averages, the median, and the ranges. Thanks to Sergo Garcia for putting these together. Of note, after the second blind, I changed my scoring scale. I had used a 0 to 100 point scale, but realistically folks scored in the 60 -100 range. I decided, after consulting with a NASA scientist, that a 0 to 5 scale with 2.5 representing an average whiskey was a better system.

Blind 1 was themed Only Bourbon.

Blind 2 was themed as Any American Whiskey.

Blind 3 was themed as ‘If it’s not Straight, You must Abate’

Blind 4 was themed as ‘The best of Gulf Coast Barrel picks’ with only local area barrel picks included.

Blind 5 was themed as ‘This Isn’t Fair’ as I included some finished whiskies as well as some finished whiskies I made myself. Yes, you can do this at home without overpaying some NDP for young whiskey with additives. See my blog post on this – https://tater-talk.com/2019/03/19/make-your-own-finished-bourbon-at-home-in-the-bottle/. Note that all American finished whiskies are class type 641, whiskey specialties, and as such are allowed to add up to 2.5% by volume HCFBM, Harmless Coloring/Flavoring/Blending Material, with no disclosure required. So making these at home with bitters or other elements is no different than what can be done commercially.

If you have not tasted completely blind, I will ensure you it can be a very humbling experience. My experience has shown that price does not equate to quality. In none of these blinds did the most expensive whiskey finish on top. Drink what you like and be careful of what you pay for.

Link to view/download graphs – https://photos.app.goo.gl/eBSxUWKo1CacEX4MA

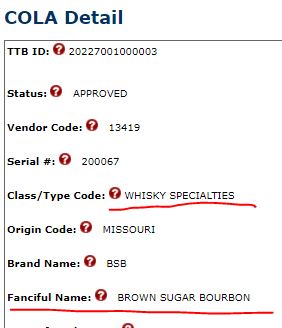

Fanciful Name Fallacy

Brown Sugar Bourbon? We all know that Bourbon by code can’t have any coloring or flavorings, so how does this grotesque whiskey exist? The answer is ‘Brown Sugar Bourbon’ is not Bourbon but a Whiskey Specialty; it’s listed in this product’s COLA application as a fanciful name.

When a spirit type does not fall under any one clear class/type designation, the TTB encourages the producer to use a fanciful name to describe it. Most products marketed as ‘Moonshine’ use that word on their label as a fanciful name; it does not exist anywhere in federal code as a class/type. It’s all marketing trend words.

‘American Single Malt’ does not exist as a class type yet plenty of producers have this listed on their label. If you check the COLA label on these, you will see they are using this as a fanciful name. The brand name is Westland and the class/type is the general category of Whiskey. This is simply Westland Whiskey with American Single Malt squeezed in between.

The TTB describes a fanciful name as “a term used in addition to the brand name for the purposes of further identifying a product”. The TTB also states that product labels should not be misleading. In the case of American Single Malt, I think it’s fair to say it correctly identifies the whiskey and provides a consumer with a better understanding of the product in the bottle, which is a whiskey derived from malted barley produced at a single distillery in the USA.

But what about Brown Sugar Bourbon? First they are using an actual class/type whiskey, Bourbon, in their fanciful name. That does not help a consumer further identify the product, it does the opposite and creates consumer confusion – is this a Bourbon distilled from brown sugar?

They use the term not once but twice and in a much larger font than the actual statement of composition which is ‘Bourbon whiskey with natural brown sugar & cinnamon flavors & caramel color’. I asked the TTB about this and their response was “they look at labels in their entirety when determining whether a label is compliant (including whether it may be misleading to the consumer).” This is also bottled at 60 proof. Bourbon by code has to be bottled at 80 proof. So the statement of composition should also include diluted with water. How far can a spirit go away from being Bourbon and the TTB allow a statement of composition to cover all? My fanciful name in large type will be Marzipan Bourbon. In the small print statement of composition it will be listed as Bourbon with 60% GNS added with coconut nibs, marzipan and caramel coloring diluted with water to 40 proof. We will see if Fred Minnick will include this in one of his tastings.

Label artwork courtesy of Todd Grube.

The Scotch Whiskey Association would never allow whiskey with these types of flavors added to be marketed as Scotch. In the USA we have the TTB that enforces what defines Bourbon. By allowing products like this into the market they are lowering the bar for what consumers think of bourbon and long term my opinion is that will have detrimental effects.

KY Bourbon trip circa 2012

I stumbled upon a word document that I saved from a 2012 road trip report to KY. My have times changed.

Kentucky Bourbon Trip

Last week, Randy Blank & I left Houston on Tuesday morning for our road trip to KY. We stopped Tuesday night in Memphis and we ate some above average BBQ at Cozy Corner (had been on Food Network’s D.D.D.) and drank some good beer at the Flying Saucer. The next day on our way to Bardstown, KY, we toured the Corvette Museum in Bowling Green, KY. The factory where GM makes all Corvettes is right next door.

We arrived in Bardstown and had a group dinner that night at local restaurant with Wes Henderson from Angel’s Envy Bourbon. Wes spoke to our group about his family’s involvement in the Bourbon industry and their decision to launch this product. While this a “sourced” bourbon that is then aged in Port barrels, they do have plans to start their own craft distillery. Wes did say this was produced for them to their mashbill specifications. They plan to introduce a cask strength version of Angel’s Envy by the end of this year. This will be aged much longer in port barrels; up to 2 years vs. 6 months. Wes brought samples of this cask strength as well as standard Angel’s Envy for us to try. I have to say while I’m not in love with this bourbon, I do love the passion Wes has for the product their family is making. If you ever get the chance to meet Wes, be sure to ask him why he is not allowed in Canada (story involves a road crew and the band INXS).

The group I’m involved with has about 70 members and about half made this trip to KY. After dinner, we had a conference room reserved at our hotel and everybody brought a bottle or 2. It was a great selection of bourbon to select from.

On Thursday, Randy & I got up early and went to friend’s house, Doug, who lives in KY out in the boonies. I think his neighbors next door might be moonshiners. We smoked 3 briskets that made the trip up with us from Texas. One member of our group works as a chef and cooked a bacon wrapped stuffed pork loin that was out this world. I’ve attached a picture – pure food porn. While we were cooking at Doug’s, most of our group went to Four Roses for barrel selection and lunch. Four Roses is at the top of my list and the group agrees, we selected 3 barrels for purchase. These barrels were recipe OBSF, OESK, and OESF – all will be bottled at proof and unfiltered. Doug has been collecting whiskey, both Bourbon and Scotch, for a very long time. He recently finished out his basement and built shelving to display his collection. It’s over 2500 bottles and I bowed down to this like I was at the altar. I have a picture of it on my phone I can show you, but Doug asked for photos not to be posted to internet.

On Friday morning, we visited Buffalo Trace to select barrels of Old Weller Antique (OWA). They rolled out 12 barrels for us to pick from. They were all the same age and all stored in same warehouse location. One might think they would all taste the same, but you would be very wrong. I brought with me a sample of off the shelf OWA. I used this as baseline to compare. After tasting the first 6 samples, I was disappointed and did not find anything I thought was better than the normal OWA. However, started with barrel 7, I knew we had some winners. On barrel 9, Randy looked at me and said If this barrel does not get selected, it’s going home with me. The group purchased barrels 7, 8, and 9 and a subgroup purchased 2 additional barrels.

After the tasting, we received a behind the scene tour. I’ve toured Buffalo Trace many times and was pleasantly surprised that we toured areas I had not seen. This included the barrel fill and barrel dump area. Attached is a picture of me at Buffalo Trace collecting some barrel char on the dump line. These char pieces fall out of barrel and are great to use on your grill or smoker. FYI – I learned to always take a glass with on tours. Also, on this line, I filled my glass directly out of the barrel with some Ancient Ancient Age – very tasty. Later we walked through a lab area where they were preparing for the next release in Old Taylor series. This will be a barrel proof, about 134 proof, bourbon and should hit your retailer in 3-4 months. A Buffalo Trace employee had a 200ml sample bottle he was passing around for us to nose. Again – my glass came in handy!

From Buffalo Trace, we made our way to Independent Stave Company. They make the barrels for several distillers. I’ve traveled back to KY many times over the years without seeing this. It is a very interesting process and while there is some automation, barrel assemble is still an art. The cooper hand picks the staves required for the barrels. Different distilleries specify how many staves per barrel, so the cooper must select the right size staves to complete barrel to the specifications.

From Independent Stave, we made our way back to Doug’s for some porch sitting and sipping bourbon. Bob and Allen Richards had arrived in KY that morning and they caught up with us at Doug’s. Doug has an amazing single malt collection that were open for anybody to sample, so Bob and Allan were both in heaven. From Doug’s we left to go to the Gazebo. Bardstown has a Best Western hotel called the General Nelson (GN). The GN has an outdoor Gazebo that starting in 2001 became a default gathering place for forum members of StraightBourbon.com. I made my first trip to GN in 2003 and have been a regular at the Gazebo table since. Hundreds of folks show up that I might see only once a year but through the years have become good friends. Hard to put in words, but suffice to say, I think it is something special.

The next morning, we visited Drew Kulsveen and KY Bourbon Distillers (KBD). I can say that tomorrow has finally arrived – KBD is now distilling. It took many years, but KBD is now filling 16 full size barrels a day. They are still working on some pump issues and plan to ramp up to 50 barrels a day. Alas, this will not be ready for sale for many years. Our group was there to taste other barrels that KBD owns. Our group had previously purchased barrels from this specific source when it was 7 years old, then again at 8 and now 9 years old. We tasted from 6 barrels and selected 2 for purchase. Honey, maple, brown sugar, cherries – a great bourbon that we will have bottled at barrel proof and unfiltered. We asked to Drew to hold for and age to 10 years 2 additional barrels. Last minute, Drew decided we might be interested in an 8 year wheated bourbon. We sampled 4 different barrels. I thought they could use some more age and passed on this one. Others disagreed and the group has purchased 1 barrel.

Drew gave us the full tour. The distillery is a thing of beauty. Drew has the Willett family original recipe and they are distilling using that mashbill. They are making both Bourbon and Rye Whiskey. After tour, Drew grabbed a drill and took a few of us up to the top of one of their rickhouses. The drill is a quick way to grab a sample from a barrel. Drew pulled samples we tasted the KBD distilled bourbon. Just a camera phone picture but thought this one was a good shot. I have been in rickhouses before, but usually they are full. Being on the 5th floor looking down at empty rickhouse and knowing it would soon be full was surreal. This KBD visit was my highlight of this trip.

After spending the morning sampling 10 different barrel proof bourbons and then some straight from the barrel, I’ll admit I went and took a good nap. Without me, the group went on the Heaven Hill (HH). HH makes many bourbons including Evan Williams and Elijah Craig. One member from California has previously purchased barrels from HH and has developed a very good relationship with them. Our group prefers to buy single barrel at barrel proof unfiltered bourbon. HH has always said no to this request in the past. They would only sell something that went into one of their standard offerings. Well, they finally said OK and decided to show off what they could do. They rolled these barrels for tasting:

Bernheim Wheated Bourbon – same product as in Parker’s Heritage Wheated Bourbon

10.6 YO – 126.9PF

11.6 YO – 122.4PF

Rye – DSP 354

3.6 YO – 126.0PF

3.6 YO – 125.6PF

Old Fitzgerald – distilled at Stitzel Weller

20YO – 130.0PF

Bourbon – Prefire HH

22.1 YO – 152.1PF

22.2 YO – 152.3PF

21.2 YO – 129.5PF

Bernheim Wheat – Straight Wheat Whiskey

7.5 YO – 136.0PF

6.2 YO – 130.2PF

Mellow Corn – corn whiskey aged in used barrels

8 YO – 125.5PF

11 YO – 139.7PF

This group did not have prior commitments for purchase at HH, so we are currently polling members to see what we might purchase. While you might get the most excited about the 20YO Stitzel Weller Old Fitz, all said it was too woody. Most thought the Rye was too young. Corn Whiskey, aka legal moonshine, usually is aged very little. The 8YO corn whiskey tasted has received some great reviews.

Late Saturday afternoon, we had a cookout at the GN. One straightbourbon member who works in a restaurant had Allen Brothers donate 32 steaks. A couple of pork butts were also smoked and I made up some Thai Slaw. Several others brought side dishes and desserts. From here, Bob, Allan, and myself went to KY Bourbon Festival Sampler. Most of the distilleries and brands have booths setup where you can get a sample, typically in a logo-ed glass that you get to keep. Jim Rutledge, Master Distiller, at Four Roses was there and we had a nice conversation with him. Then back to the Gazebo. I was designated driver that night, so my participation was very limited. I did sample of Cabin Still at 90 proof from the 70’s that was remarkable.

We started road trip back early Sunday morning. We elected a different route coming home – stopping at casino resort in Biloxi on Sunday night. This route takes us route by a cousin of mine in Hartselle, AL, so able to stop and have a brief visit. Randy & I both won a little money gambling (although him way more than me). The other great thing about this route is it passes by Don’s Specialty Meats outside of Lafayette, LA. I can’t pass on fresh hot cracklin and also stocked up on boudin, crawfish tail meat (from LA – not China), some rabbit sausage and few other items.

Overall, this was the best trip I have been on the KY. Looking forward to next year’s version.